Boundary Conditions

Boundary Conditions define how the model is externally constrained.

All models must be attached to some external point or points of support. You may define these points of support as completely restrained or as

partially restrained with a Spring. You can

also define a spring support that has stiffness in only one direction

with tension-only or compression-only springs.

For additional advice on this topic, please see the RISA Tips & Tricks webpage at risa.com/post/support. Type in Search keywords: Boundary Conditions.

Creating and Modifying Boundary Conditions

There are a number of ways to create or modify boundary conditions. You

may view and edit the data in the Boundary Conditions

Spreadsheet, you may double-click a joint to view and edit its properties,

or you can use the Modify Boundaries tool to graphically assign or modify a possibly

large selection of boundary conditions.

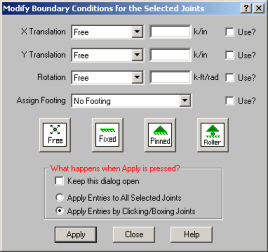

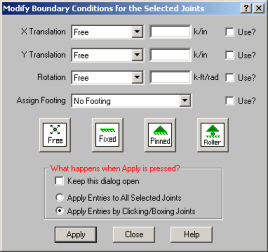

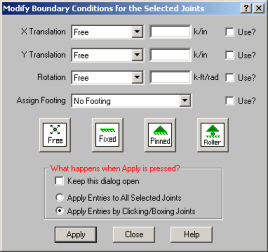

Modify Boundary Conditions for

Joints

The graphical Modify Boundary tool discussed here lets you specify and modify boundary conditions graphically. To use this, you will typically

specify the new boundary condition, then select the joints that you want

to assign or modify.

You can modify or assign joints one at a time by selecting the

Apply by Clicking/Boxing option and then click on the joints you wish to

modify. You may also modify or assign entire selections of joints by selecting

the joints first and then use the Apply to All Selected option.

The parameters shown below are the same as those on the Boundary Conditions

Spreadsheet and are described in Boundary Condition

Options. Use the arrow buttons to select the boundary condition.

The Use? check boxes next to the data fields indicate whether

the particular parameter will be used or not when the modification is

applied. If the box next to a field is checked, that parameter will

be applied to any selected joints If the box is NOT checked, the

parameter will NOT be applied, even if a value is entered in the field.

This lets you easily change one or two parameters on joints without affecting

all the rest of the parameters.

-

If

there is not a model view already open, click  on the RISA Toolbar

to open a new view and click

on the RISA Toolbar

to open a new view and click  to turn on

the Drawing Toolbar if it is not already displayed.

to turn on

the Drawing Toolbar if it is not already displayed.

-

Click

the  Boundary Conditions button on the Home tab and define the boundary condition. Check the Use? Box for the items to apply.

Boundary Conditions button on the Home tab and define the boundary condition. Check the Use? Box for the items to apply.

-

You

may apply the boundary condition by choosing joints on the fly or apply

it to a selection of joints.

To choose joints on the fly, choose Apply Entries

by Clicking/Boxing Joints and click Apply. Click/Box

the joints with the left mouse button.

To apply the boundary condition to a selection of joints,

choose Apply Entries

to All Selected Joints and click Apply.

Note

- To apply more boundaries

with different conditions, press CTRL-D to recall the Boundary Conditions Dialog.

- You may also view

and edit boundary conditions by double-clicking on a joint.

- You may also specify

or edit boundary conditions in the Boundary Conditions Spreadsheet.

- You may undo any

mistakes by clicking the Undo

button.

button.

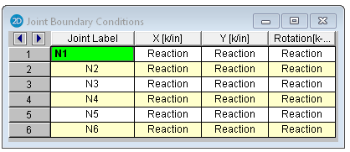

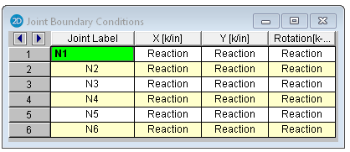

Boundary Conditions Spreadsheet

The Boundary Conditions Spreadsheet records the boundaries for

the joints and may be accessed by selecting Boundary Conditions on

the Spreadsheets Menu.

The Joint Label column contains the label of the joint that is restrained.

The remaining columns record the boundary conditions that apply to the

joint. There are three degrees of freedom for

each joint (2 translation, 1

rotation), so there are three columns for degrees of freedom.

The boundary conditions are entered in these remaining columns by selecting

the cell, clicking  and choosing from

the boundary options. You may also type them in directly.

and choosing from

the boundary options. You may also type them in directly.

Boundary Condition Options

Free joints have no restraint in any of the degrees of freedom and need

not be listed on the Boundary Conditions Spreadsheet. The following

are the valid boundary condition options that may be used for the three

degrees of freedom.

Note

- Models

that contain compression-only or tension-only springs must be iterated until

the solution converges. Convergence is achieved when no more load

reversals are detected in the springs. During the iteration process,

each spring is checked, and if any springs are turned off (or back

on), the stiffness matrix is rebuilt and model is resolved.

This can take quite a bit longer than a regular static solution.

- With this iteration procedure it is possible to run into a phenomenon known as "clapping". This occurs when a compression-only spring keeps going between a tension force present (where the spring is removed) to a compression force present (where the spring is re-added). This can be somewhat common in non-linear solutions. If you run into this phenomenon, you may see the program give Error 1162. The fix is to very slightly adjust either the loading or the spring/element stiffness to get the offending spring out of the range where it can bounce back and forth. Another option would be to move the location of the soil spring slightly so it's not right at an inflection boundary.

- You can enter the

first letter of the option ("R" for Reaction, "S"

for Spring, etc.) rather than typing out the entire code. RISA-2D fills in the rest automatically. The exception

is the Tether entry, where the full word does have to be entered. After Tether, the primaryjoint needs to be entered (for example, Tether N2)

Boundary Condition at ALL Joints

The entry "ALL" may be entered in the Joint Label

field. The boundary conditions entered on this line will be applied

to ALL the joints not otherwise listed. This is useful if you should

want to lock certain directions of movement for all or most of the joints.

Note

- If a joint is explicitly

listed with boundary conditions, those boundary conditions override the

"ALL" conditions for all 3 directions. The "ALL"

specified boundary codes apply only to those joints NOT otherwise listed

on the Boundary Conditions Spreadsheet.

- When using the "ALL" command, boundary conditions are no longer graphically displayed.

Reaction Boundary Condition

The "R" code, for Reaction, specifies full restraint for

the indicated direction. No movement will be allowed in the indicated

direction for this joint. Furthermore, the reaction will be calculated

at this joint, for this direction.

Fixed Boundary Condition

The "F" code, for Fixed, specifies full restraint for the

joint in the indicated direction. The difference between "Fixed"

and "Reaction" is that for the "Fixed" code, no reaction

is calculated. The "Fixed" condition actually removes

the degree of freedom from the solution, which is why the reaction value

is not available. If you aren't interested in the reaction value,

using the "Fixed" code will result in a slightly smaller model

and less output.

Spring Boundary Condition

The "Snnn" code, for Spring, models a spring attached to the joint in the

indicated direction. The "nnn" portion of the code is the numerical magnitude of the springs' stiffness. The units for the spring stiffness depend upon whether the spring is translational

or rotational. The appropriate units are shown at the top of the

column.

For example, if a spring of stiffness 1000 Kips per Inch were desired

in the X direction at a particular joint, for that joint you would enter

'S1000' for the X direction boundary condition.

Compression-Only Springs

The "CSnnn" code, for Compression-Only Springs, models a one way "compression-only"

spring attached to the joint in the indicated direction. This

spring has stiffness for negative displacements and NO stiffness for positive

displacements. The "nnn" portion of the code is the numerical magnitude of the springs' stiffness. The spring

stiffness units are the same as those for a normal spring. Compression-only

springs are useful as soil springs when analyzing foundations that

may have uplift.

For example, if a compression-only (CS) spring with a stiffness of 500k/in

were desired in the Y direction at a certain joint, you would enter 'CS500' for

the Y direction boundary condition.

This means that all displacements at this joint in the negative Y direction

will be resisted with a stiffness of 500k/in. However, the joint

is free to move in the positive Y direction.

- When

a model contains T/C only springs, the program must iterate the solution

until it converges. Convergence is achieved when no more load reversals

are detected in the T/C only springs. During the iteration process,

each T/C only boundary condition is checked. If any springs are

turned off (or turned back on), the stiffness matrix is rebuilt and

model is resolved. For models with lots of T/C only elements, this

can take a bit longer than a regular static solution.

Tension-Only Springs

The "TSnnn" code, for Tension-Only Springs, models a one way "tension-only"

spring attached to the joint in the indicated direction. This

spring has stiffness for positive displacements and NO stiffness for negative

displacements. The "nnn" portion of the code is the numerical magnitude of the springs' stiffness. The spring

stiffness units are the same as for a normal spring.

For example, if a tension-only (TS) spring with a stiffness of 500k/in.

were desired in the Y direction at a certain joint, you would enter 'TS500' for

the Y direction boundary condition.

This means that all displacements at this joint in the positive Y direction

will be resisted with a stiffness of 500k/in. However the joint

is free to move in the negative Y direction.

- When

a model contains T/C only springs, the program must iterate the solution

until it converges. Convergence is achieved when no more load reversals

are detected in the T/C only springs. During the iteration process,

each T/C only boundary condition is checked. If any springs are

turned off (or turned back on), the stiffness matrix is rebuilt and

model is resolved. For models with lots of T/C only elements, this

can take a bit longer than a regular static solution.

TetheredJoints

You may tether any or all of the joint degrees of freedom to another

joint. See Tethering Joints for more

information.

Story Drift Joints

- The Boundary

spreadsheet is also used to record joints to be used for story drift calculation.

For example, to indicate that a particular joint is to represent the fourth

story level for X direction drift, you would enter “STORY 4” for the X

direction boundary condition for the joint. These STORY entries

may only be made in the translation degrees of freedom. See Drift

for more information.

Boundary Conditions at Wall Panels

If the edge of a wall panel is to be viewed as continuously pinned or fixed, then the boundary condition for that wall must be set in the wall panel editor. Situations can arise where there is a difference between the wall panel edge boundary condition and the boundary condition defined at a joint along that edge. In these situations the joint boundary condition will always govern for that joint. However, the rest of the edge will be based on the wall panel's boundary conditions.

to turn on

the Drawing Toolbar if it is not already displayed.

to turn on

the Drawing Toolbar if it is not already displayed.![]() Boundary Conditions button on the Home tab and

Boundary Conditions button on the Home tab and  button.

button.

![]() and choosing from

the boundary options. You may also type them in directly.

and choosing from

the boundary options. You may also type them in directly.